Components Of The Q-Fusion Fittings

Together, electrofusion fittings and polyethylene pipes enable utilities, designers and contractors to create fully welded pipe networks. Joints are critical points in any pipe network. The production quality, reliability, and flexibility of Fusionís electrofusion fittings buy you peace of mind and certainty.

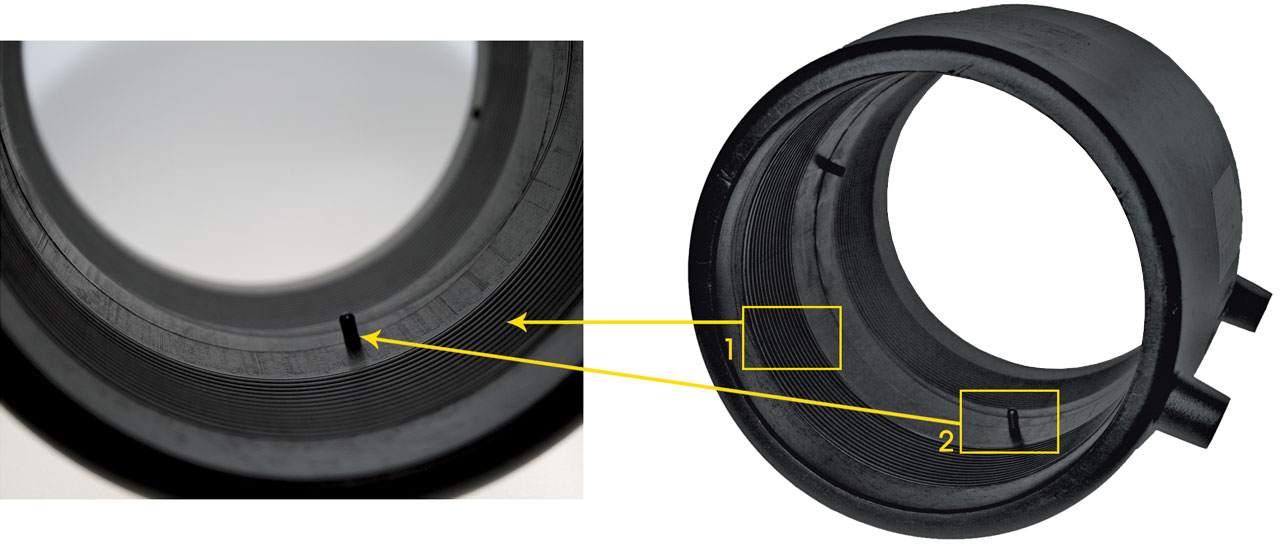

1) Q-Fusion Pin

When the electrofusion welding machine is connected to the pin and the machine is adjusted for welding, the operator just needs to press go!

2) Indicators

The pressure created by the expanding molten plastic in the joining area inside the fitting during the electrofusion process will force out the indicator lugs. This is a visible sign that the necessary joining pressure has been achieved.

3) Moulded-in welding parameters

Information provids fitting size, material (PE80 or PE100), applicable pipe SDRs and pressure ratings for gas and water applications.

4) Barcode

The barcode carries the welding parameters that can be shown on an electrofusion welding machine equipped with a barcode scanner.

Quality control is central to the success of Fusionís fittings. The barcode provides full traceability right down to the polymer batch; the raw material from which the fittings are manufactured.

1- Element

To promote join quality, all fusion elements are covered by a thin layer of polyethylene for make a perfect weld and prevent of the oxidation of elementís wire.

2- Pipe Stops

Q-Fusion couplers have removable pipe stops. The stops ensure pipes cannot be inserted past the midpoint, but can be removed for use in, for example, repair situations.

Back to browsing